Not known Factual Statements About Soda Blasting Auckland

Everything about Soda Blasting Auckland

Table of ContentsSome Of Soda Blasting AucklandSoda Blasting Auckland Fundamentals ExplainedWhat Does Soda Blasting Auckland Mean?Soda Blasting Auckland - The FactsFacts About Soda Blasting Auckland RevealedThe Buzz on Soda Blasting Auckland

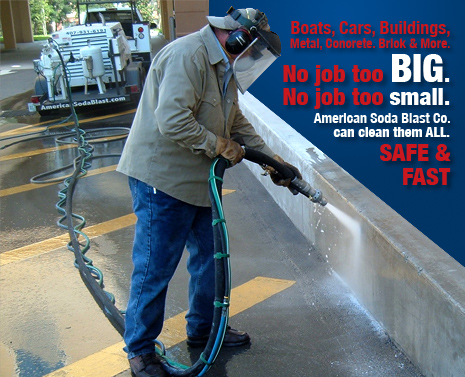

Industrial cleaning with blasting modern technology eliminates material forcibly particulates on to a surface area under high pressures. Dry Soft drink blowing up gets rid of surface area crud without needing to clean and get rid of waste water or cause further damage or spills. The worst issue in blasting is the presence of wetness in the system.

The Best Strategy To Use For Soda Blasting Auckland

The very same amount of wet sand would hit the target with even more force, as well as would not blow in the wind.

Blowing up with soft drink is still abrasive, however significantly extra mild than sandblasting, it will not cause damages to the surface that is being cleaned. A soft drink blast will certainly use much less stress than conventional sandblasting, as well as blowing up soda media is so eco-friendly that it has actually also been used to tidy historical symbols like the Sculpture of Freedom! The rough blasting power that is used with soda blasting can be used to get rid of paint, oil, mold and mildew, oil, or residue without damaging the surfaces underneath, like glass, chrome, or even slim sheet steel.

Making use of a reduced pressure but high volume blasting machine, pressed air is drawn through bring the salt bicarbonate with it. This functions as a non-damaging unpleasant suitable for use on a large range of surface areas. The salt bicarbonate blows up as it hits the surface, carefully raising as well as removing pollutants away as it does.

A Biased View of Soda Blasting Auckland

In the past, the only method you could eliminate paint or various other unsightly materials from an infected surface, was to chip it off, sand it, make use of harsh chemicals or sand blast it. Currently there is Sodium Bicarbonate BLASTING! Soft drink Blasting is a process that can remove practically any kind of surface in an effective and also secure way.

It also gets rid of the translocation of oil and also grease. The security of sodium bicarbonate to workers is well recognized, because it has actually been in usage for some 160 years. The bicarbonate buffer system is the major additional mobile barrier in the body, hence sodium bicarbonate becomes part of the body's regular chemistry.

As a solid buffer for acids and also alkalis, soda gets rid of acidic problems on the surface area of the substratum. For conditions with high acidic levels, acid rainfall or central heating boiler fly ash, blowing up with soft drink will decrease coating failings. As long as sodium bicarbonate gets on a ferrous steel read this article surface area, corrosion will certainly not develop.

All about Soda Blasting Auckland

Soft drink buffers acids as well as prevents the release of complimentary steel ions and also avoids corrosion. Soft drink blast media can be liquified in fresh water.

Standard qualities of soft drink media (without any kind of tough aggregates) do not profile steel. When an operator eliminates a finishing from a metal surface, he or she exposes the existing support pattern under the layer.

For projects where the layer is covered with oil, carbon, salt or various other impurities, the extra typical blowing up techniques require the finish to be totally cleaned up before blasting. This is called for to ensure that the pollutants externally of the covering not be driven through the layer and also right into the surface area of the substrate, causing future layer failing (Soda Blasting Auckland).

See This Report on Soda Blasting Auckland

The process of Soda, Blasting was initial created see this in 1972, when engineers in the USA were trying to develop a technique of cleaning up the Statue of Liberty which would certainly not harm the surface and also be eco-friendly. From this procedure Soda blowing up was birthed and has given that been used around the globe as an effective eco-friendly cleaning process that works on practically any type of surface area.

The capacity to readjust pressure between such a huge range allows the most stubborn or delicate of materials to be cleaned. DK Soda, Blasting utilize the most reliable variety of machinery on the market today, all our devices have been particularly produced with the highest possible of standards and are configured to use the finest of Soda.

Much, soft drink blowing up noises like an extremely efficient means to get rid of contamination without damaging surfaces. But what's the downside? As with all completely dry blowing up strategies, the downside is dirt. Any kind of dry blowing up media creates dirt that floats almost everywhere and also gets involved in every little thing. To avoid the dust from finish the job, containment should be utilized.

All about Soda Blasting Auckland

In other instances, such as large, awkwardly designed projects or jobs that can not be easily moved (an auto parking garage for example), containment can be a time consuming as well as costly step. No blasting process can genuinely be dustless, yet with vapor abrasive blowing up, the dirt is decreased drastically contrasted to dry blowing up.

The Graco Eco, Repartee 2 Vapor Abrasive Blast Systems feature a pump that pressurizes a pot of water and also media. As water is metered into the pot, the media moves right into the blast circuit and through the hose pipe and also nozzle throughout browse this site blasting. The accurate control of the wetted media leads to substantial dust reduction without sacrificing efficiency.

47-0. 95 L) of water departures the nozzle per minute.